Warehouses Management

Efficient Warehousing Solutions for Seamless Supply Chains

Warehouses management system is a multifaceted and critical aspect of efficient supply chain operations, encompassing a wide range of processes, procedures, and strategies that are essential for the effective storage, handling, and movement of goods within a warehouse facility. At Patliputra Logistics, we understand the fundamental importance of warehouse management in optimizing overall supply chain performance.

Benefits

With Warehouses Management, you can achieve up to:

Warehouses Management System

Agile Task Management

Agile task management in warehouse execution refers to the ability to quickly adapt and manage tasks efficiently in response to changing demands. It involves using agile methodologies to streamline workflows, allocate resources effectively, and enhance productivity in warehouse operations. This approach enables warehouses to respond promptly to customer orders, optimize inventory management, and improve overall operational efficiency.

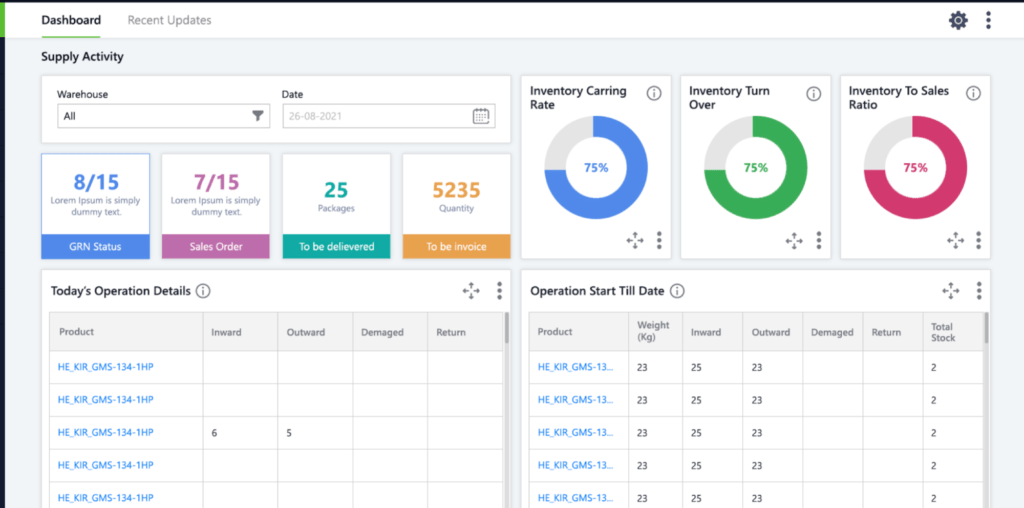

Real-time inbound and outbound processing

Real-time inbound and outbound processing in warehouse management refers to the ability to manage and track the movement of goods as they enter and leave a warehouse facility in real time. This involves using advanced technologies such as RFID, barcode scanning, and automated systems to efficiently process incoming and outgoing shipments. Real-time processing allows for accurate inventory management, timely order fulfillment, and improved visibility into warehouse operations.

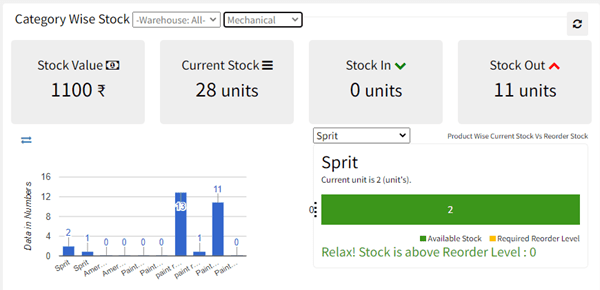

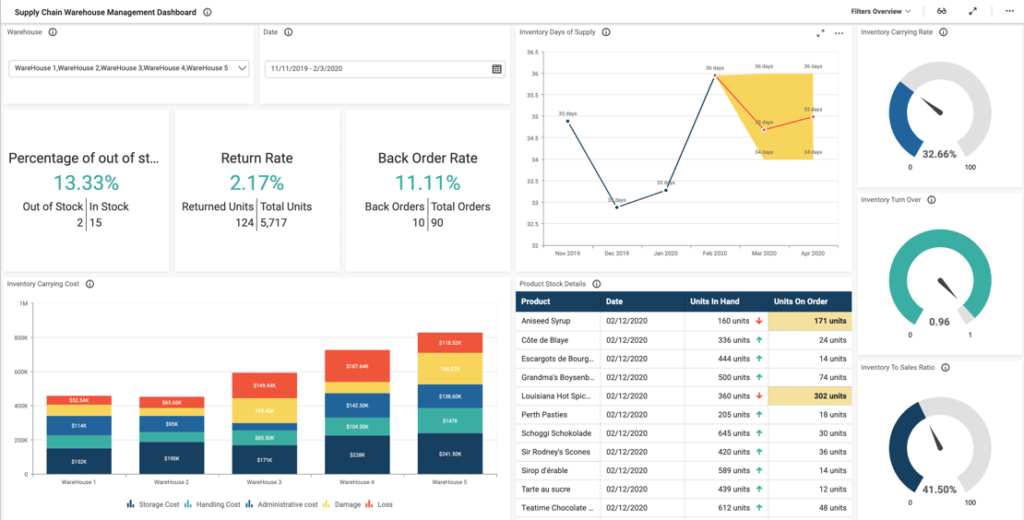

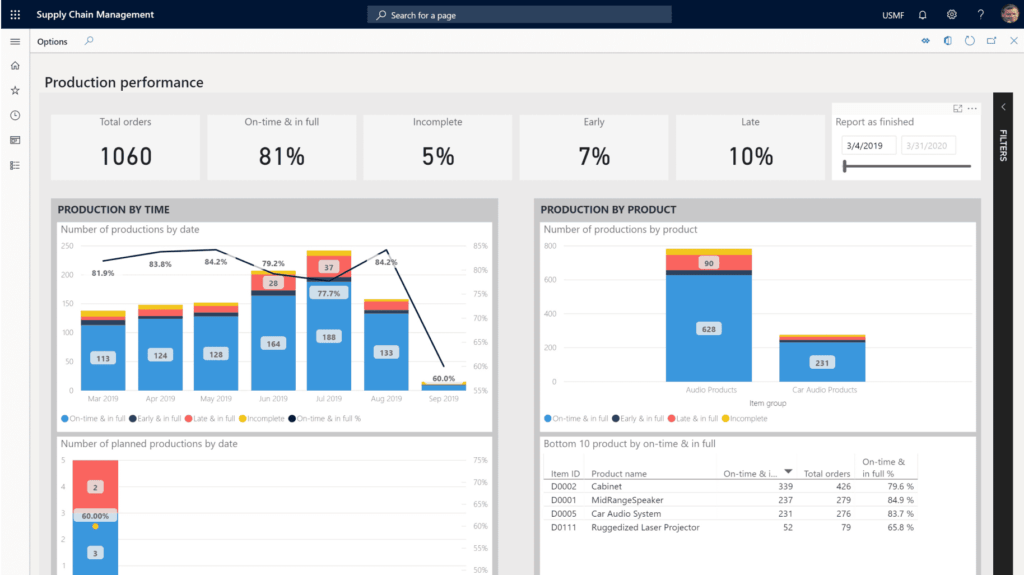

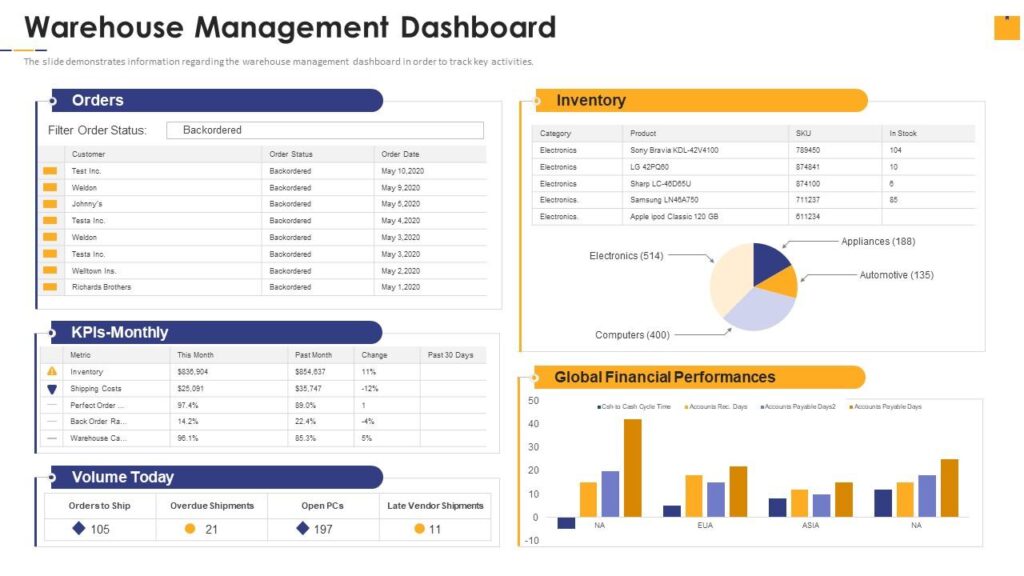

Advanced Visibility and Analytics

Advanced visibility and analytics in warehouse execution refer to the use of advanced technologies and data analysis tools to gain real-time insights into warehouse operations. This includes tracking inventory levels, order statuses, and warehouse performance metrics using sensors, RFID, and IoT devices. These insights enable warehouse managers to make informed decisions, optimize workflows, and improve overall efficiency.

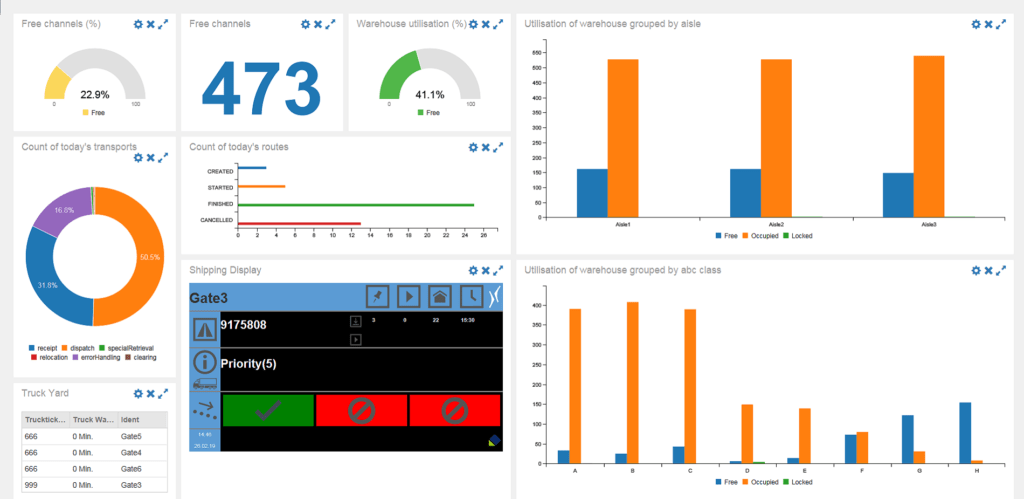

Synchronized Interleaving

Synchronized interleaving in warehouse execution refers to the coordinated movement and storage of goods within the warehouse to optimize space utilization and workflow efficiency. This approach involves strategically interleaving different product types or SKUs in a way that minimizes travel time and maximizes the use of available space.

Dynamic Workflow Enablement

Dynamic workflow enablement in warehouse execution refers to the ability to adapt and optimize operational workflows in real-time based on changing demands, priorities, or conditions within the warehouse environment. This capability allows for flexible task allocation, resource utilization, and process adjustments to maximize efficiency and responsiveness.

Intelligent inventory management

Intelligent inventory management in warehouse management refers to the use of advanced technologies and analytics to optimize inventory levels, storage, and movement within a warehouse. It involves the use of algorithms and predictive analytics to forecast demand, optimize stock levels, and automate replenishment processes.