Streamlined Returns and Recovery Solutions for Efficient Reverse Logistics Management

Reverse logistics involves the process of managing the return, repair, recycling, and disposal of products and materials in a supply chain. It encompasses activities such as product returns, refurbishment, and redistribution. Reverse logistics aims to optimize the value of returned goods, reduce waste, and minimize environmental impact. It plays a critical role in sustainability efforts and can contribute to cost savings and customer satisfaction.

Need For Reverse-Logistics Process

Reverse-logistics is crucial for managing product returns, repairs, and disposal efficiently. It minimizes losses, recovers value from returns, and supports environmental sustainability through recycling and responsible disposal practices. Efficient reverse logistics leads to cost savings, improved customer retention, and environmental benefits.

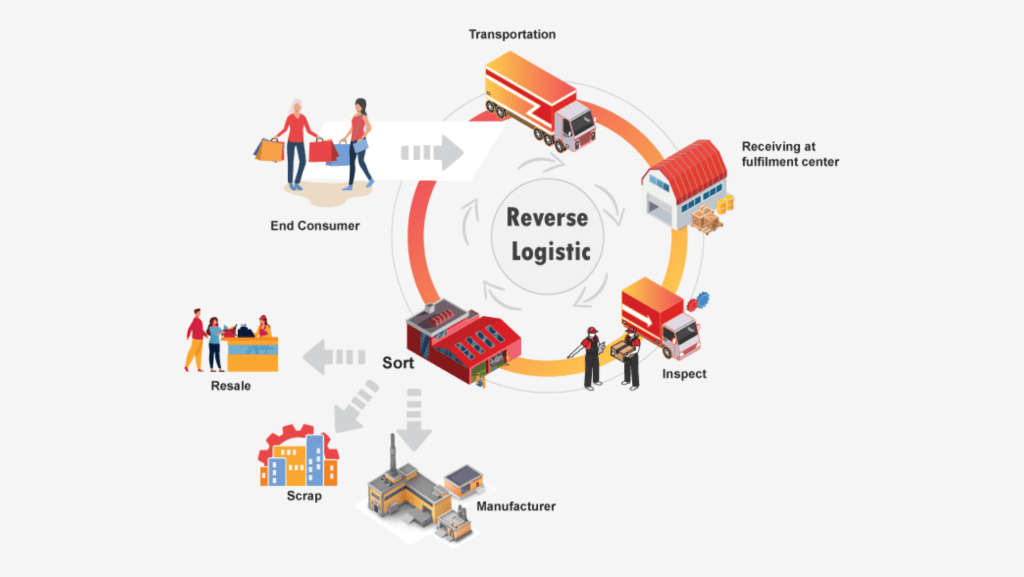

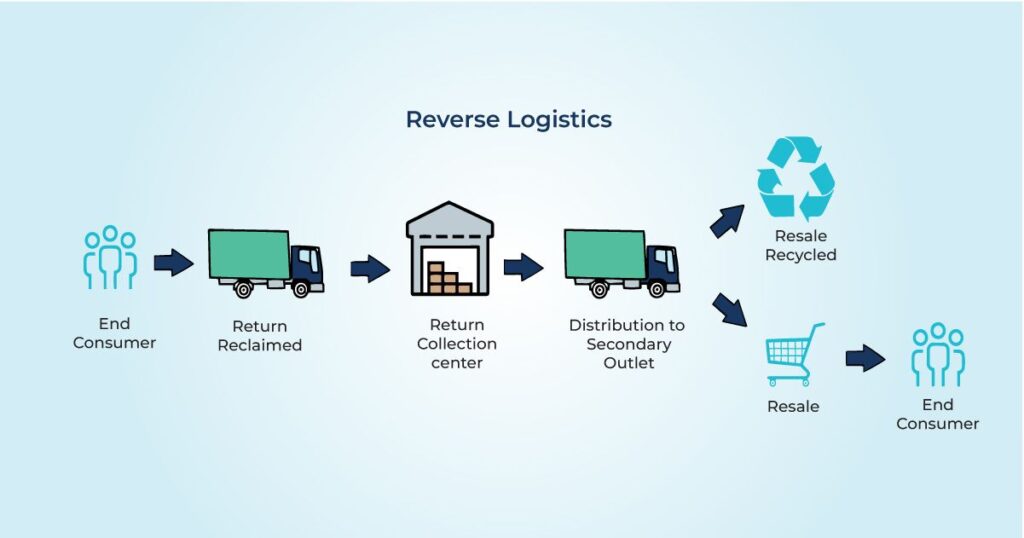

Reverse-Logistics Process

Reverse-logistics refers to the process of managing the return of goods from the point of consumption to the point of origin. It involves activities such as product returns, recalls, repairs, recycling, and disposal. The goal is to optimize these processes to recover value from returned products, minimize waste, and ensure environmental sustainability. Effective reverse logistics requires efficient handling, transportation, and disposition of returned items, often involving coordination with multiple stakeholders in the supply chain.

Benefits of Reverse-Logistics

Environmental Sustainability

Cost-Effective

Inventory Optimization

Better Supplier Collaboration

Data Analysis for Improvement

Customer Loyalty and Retention