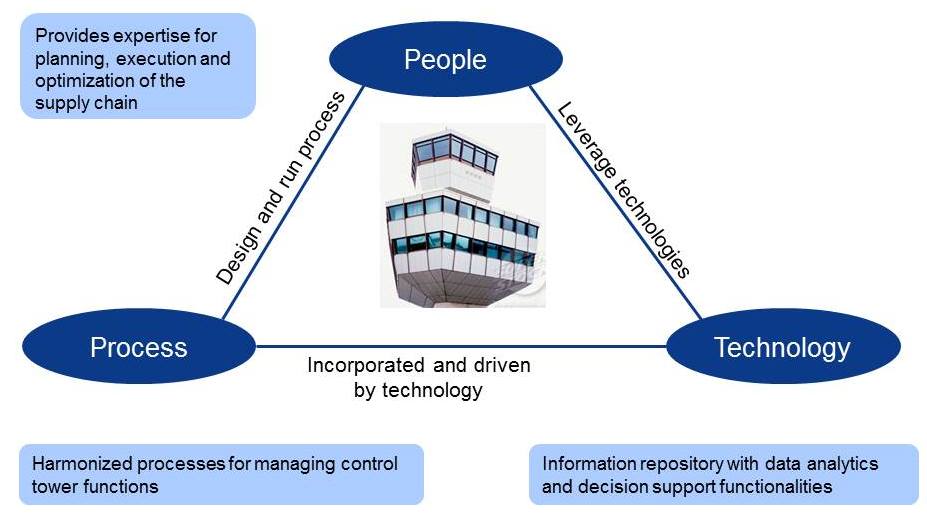

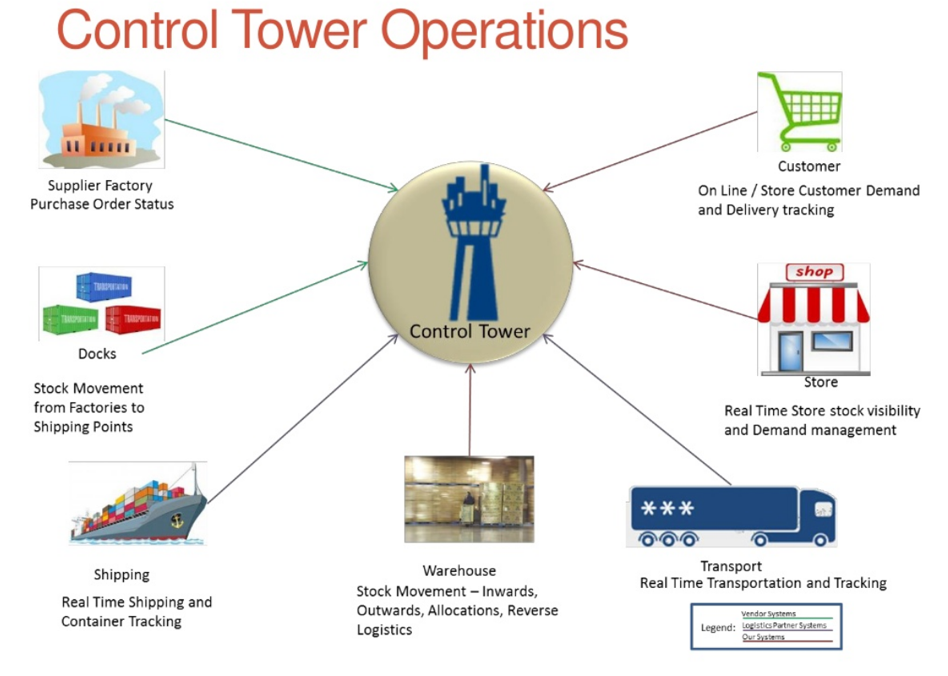

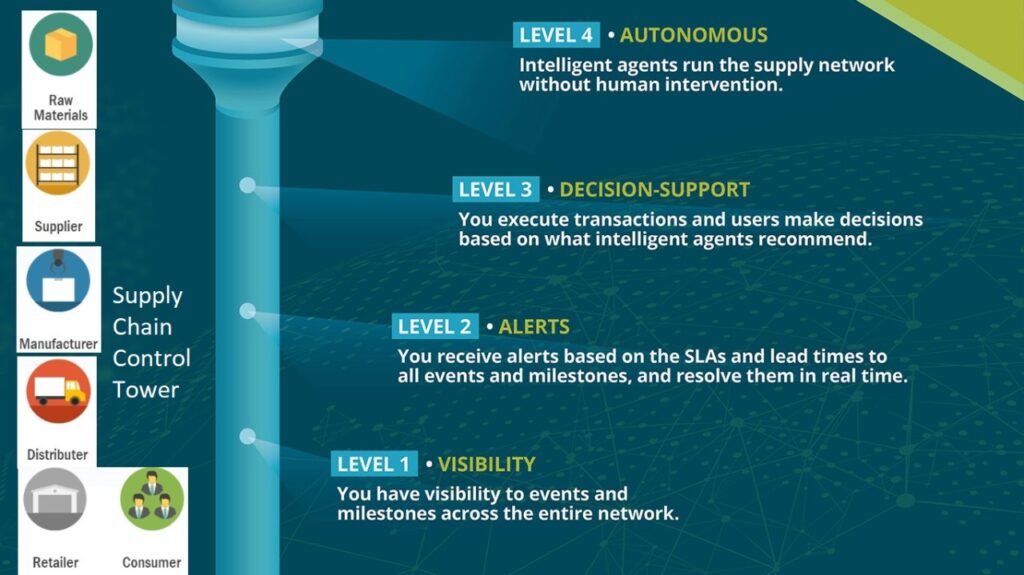

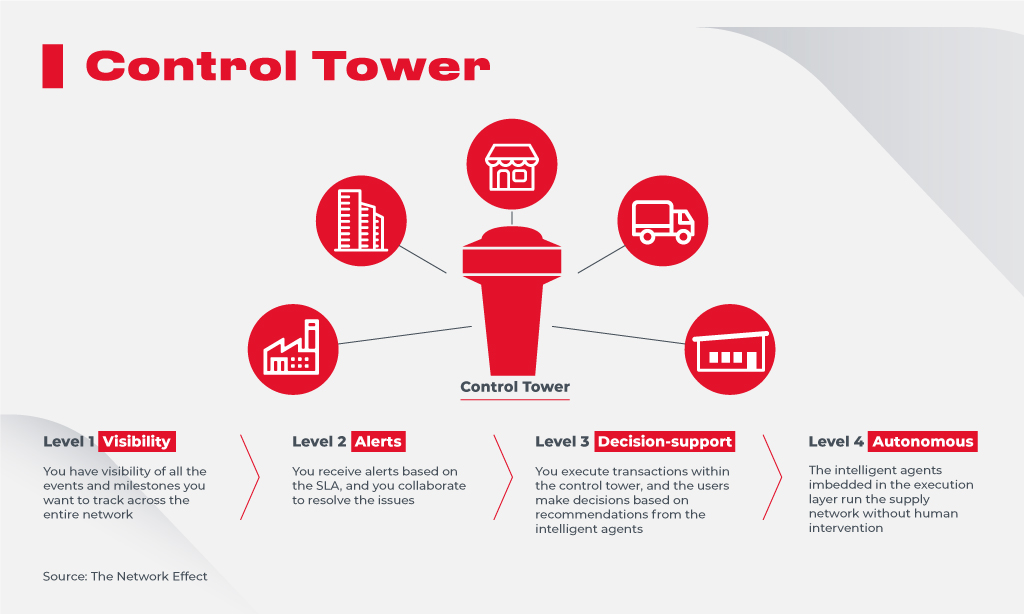

A supply chain control tower is traditionally defined as a connected, personalized dashboard of data, key business metrics, and events across the supply chain. A supply chain control tower enables organizations to understand, prioritize and resolve critical issues in real-time more fully.

What are supply chain control towers?

Supply chain executives are under enormous pressure to provide customers with what they need, when and where they need it, while also optimizing supply operations and achieving cost-saving goals. This is especially challenging in times of unpredictable yet inevitable vulnerabilities and disruptions.

A smarter control tower should provide end-to-end visibility across the supply chain, particularly into unforeseen external events. It should use advanced technologies, such as AI with machine learning, to help you break down data silos, reduce or eliminate manual processes and get real-time actionable insights.

A smarter control tower enables collaboration across teams and trading associates and preserves organizational knowledge to improve and accelerate decision-making and outcomes. Ultimately, this helps you better predict disruptions, improve resiliency, manage exceptions, and respond to unplanned events.

Types of Control Towers

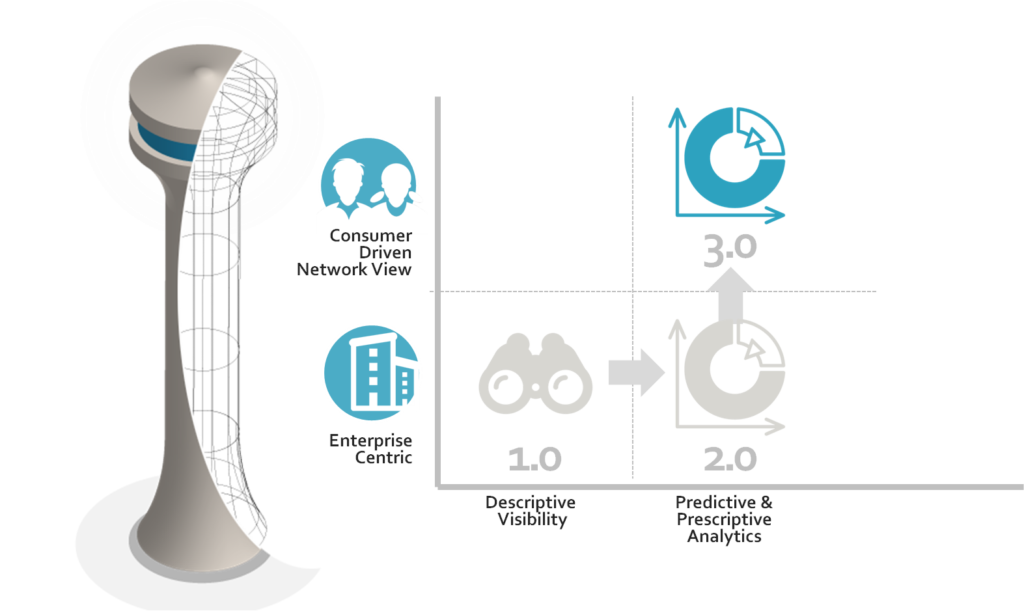

Before diving into specifics, it’s essential to recognize that not all control towers are the same. Understanding the different types can help you determine which one will best benefit your business. Control towers can be categorized into two main classes based on their functions:

Analytical Control Towers

These control towers excel at the analytical aspect of their purpose. They consolidate data, diagnose exceptions, and prescribe outcomes based on set parameters.

For example, an analytical control tower might predict the most cost-efficient truck route using historical data on average travel time. It can also aggregate other data, such as a company’s on-time delivery track record and average fuel usage. However, analytical control towers do not act on the data; they cannot autonomously execute any plans. Therefore, human intervention is required to review the data and make decisions.

Operational Control Towers

These control towers take predictive analytics further by not only generating optimal outcomes but also implementing them automatically.

Key capabilities and benefits of supply chain control towers

Real-Time, End-to-End Visibility

Achieve comprehensive visibility across your supply chain with a control tower that integrates data from siloed systems and external events. Access personalized dashboards that deliver actionable insights into potential disruptions, enabling proactive exception management.

Predictive and Prescriptive Decision Support

Enhance disruption prediction and resilience with smart alerts and real-time actionable insights. Understand the upstream and downstream impacts of events on customers, allowing you to prioritize your responses effectively.

Collaborative Information Sharing

Improve collaboration and exception management throughout your supply chain with AI-powered resolution rooms, digital playbooks, and supply chain applications. Quickly address unplanned events and refine execution to drive KPI performance.

Reduced Costs

Effective communication and information sharing between shippers and truckers can lead to shorter delivery times and reduced costs.

Consider a scenario where a shipment is delayed at its destination due to missing information on the Bill of Lading. Resolving this issue could take at least one business day for assessment and handling, plus another business day to resolve and pay demurrage charges. With a control tower and appropriate parameters, these exceptions can be identified and addressed before arrival, preventing delays and additional costs.

Autonomous Decision Making

Autonomous decision-making is a game-changing feature of control towers and represents the future of the supply chain industry. While collecting data, analyzing it, and running scenarios to optimize efficiency and minimize costs is valuable, it remains just data and plans without action, relying on human intervention for execution.

Control towers take this process further by automatically executing the most effective strategies. This level of autonomy leverages data and information to implement solutions that would previously have required hundreds of human hours in a fraction of the time, revolutionizing your business operations.