Control Tower

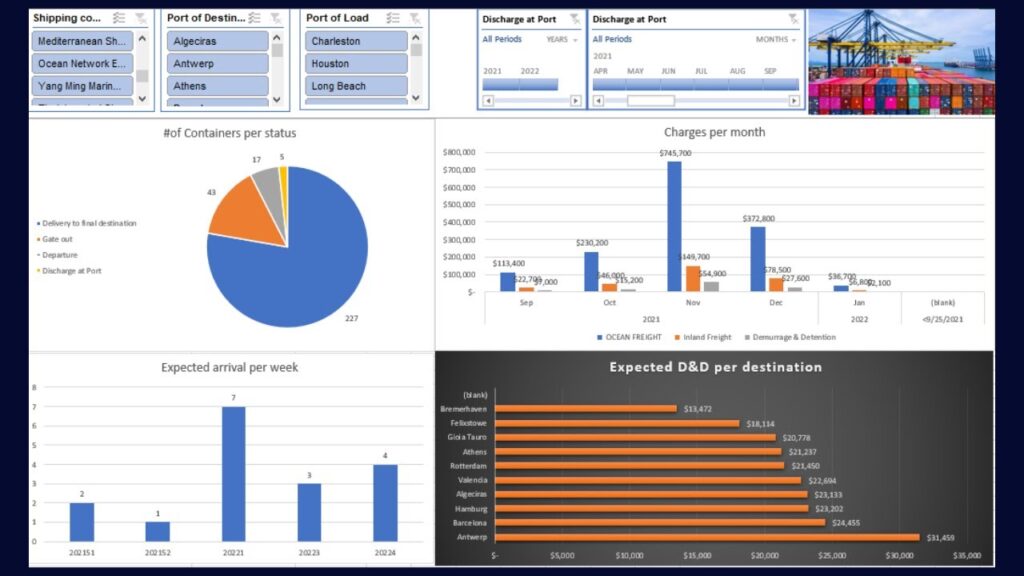

A supply chain control tower is traditionally defined as a connected, personalized dashboard that provides real-time data, key business metrics, and event alerts across the entire supply chain. This centralized platform enables organizations to gain a comprehensive understanding of their supply chain operations, prioritize critical issues, and take proactive measures to resolve them efficiently.

In today’s dynamic business environment, supply chain executives face increasing pressure to meet customer demands while optimizing supply operations and achieving cost-saving objectives.

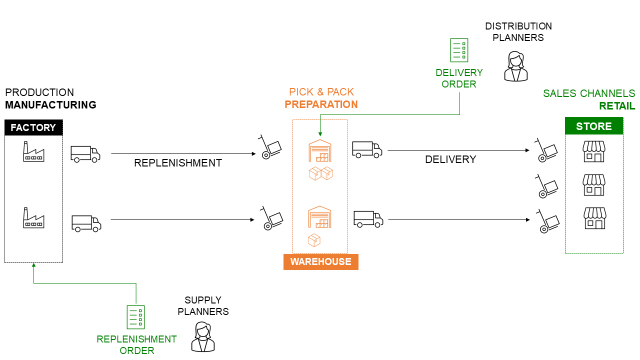

Network design

Network Design within a control tower involves strategically mapping out the structure and flow of a supply chain network. It includes determining the optimal location of facilities, distribution centers, and transportation routes to ensure efficient operations, minimize costs, and meet customer demands. By leveraging advanced algorithms and data analysis, organizations can optimize their network design to enhance agility, resilience, and responsiveness in dynamic market environments.

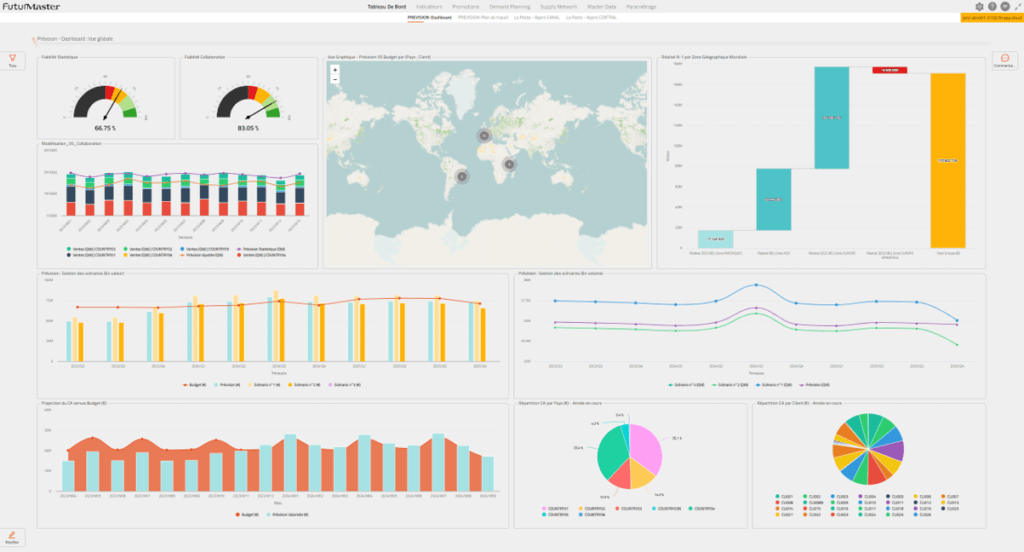

Demand planning

Demand Planning in a control tower is a strategic process that utilizes historical data and advanced analytics to forecast future demand patterns. By analyzing trends and customer behavior, organizations can optimize inventory levels, minimize stockouts, and enhance customer satisfaction. This proactive approach helps businesses align supply with demand, reduce costs, and improve overall operational efficiency.

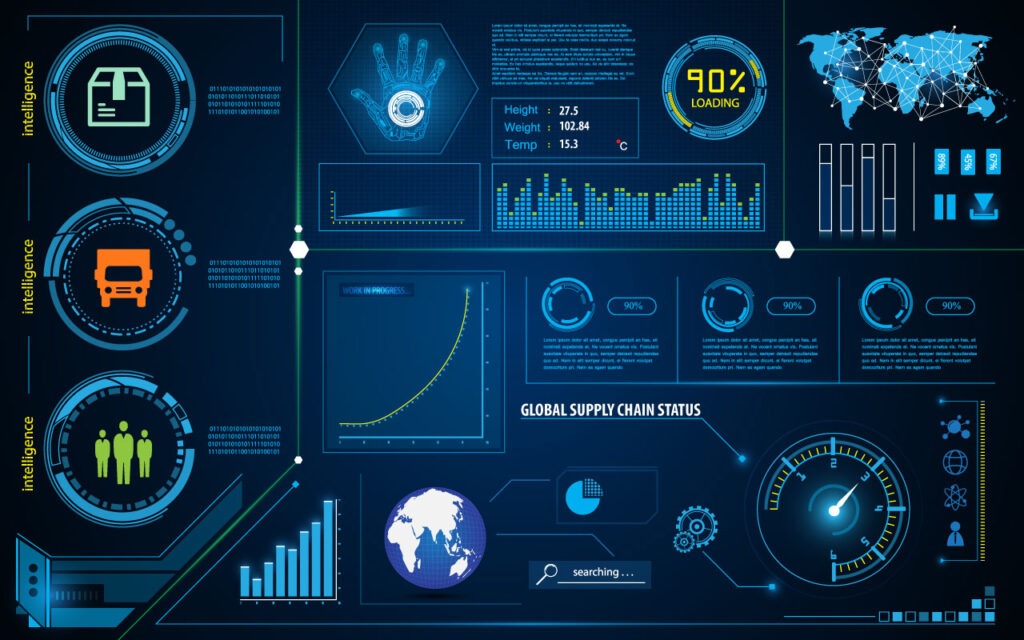

Real-time end-to-end visibility

Real-time end-to-end visibility in supply chain control towers enables continuous monitoring and analysis of all stages, from procurement to delivery. This comprehensive view allows for proactive decision-making, optimizing operations, and enhancing customer satisfaction by ensuring timely and efficient delivery. With real-time insights, businesses can quickly identify and resolve issues, improving overall supply chain performance.

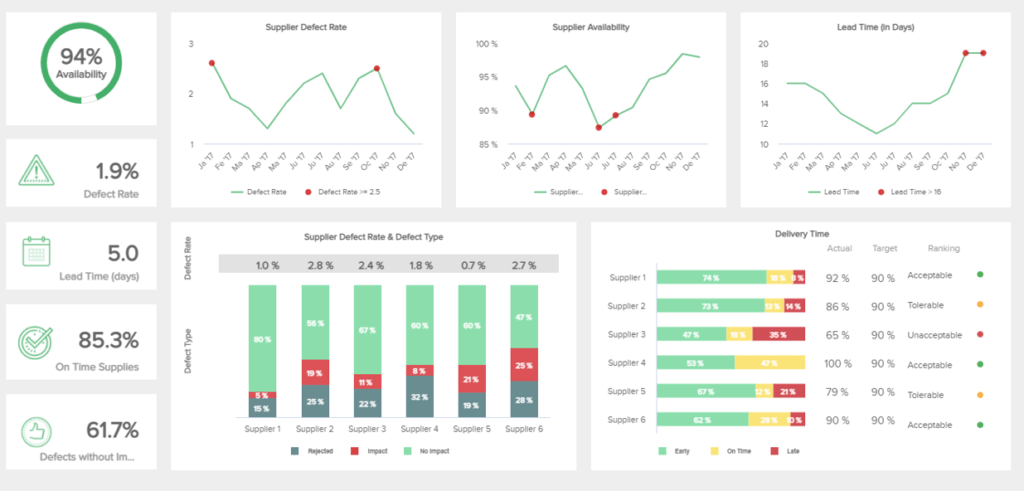

Proactive alerts & exception management

Proactive alerts and exception management in supply chain control towers play a crucial role in maintaining operational excellence. These systems use advanced analytics and real-time data to detect and address potential issues before they escalate, ensuring smooth operations and customer satisfaction. By proactively managing exceptions, businesses can minimize disruptions and optimize their supply chain performance.

Predictive insights

Predictive insights in supply chain management leverage data analytics and AI to forecast future trends and potential issues. By analyzing historical data and patterns, businesses can make informed decisions, anticipate demand fluctuations, optimize inventory levels, and enhance overall supply chain efficiency. Predictive insights enable proactive strategies, reducing costs and improving customer satisfaction.

Customer Benefits

Real-Time Visibility

Real-time visibility in supply chain control towers provides instant insights for proactive decision-making and operational agility.

Scalable and Adaptable

Scalable and adaptable solutions in supply chain control towers ensure flexibility and efficiency in dynamic logistics environments.

Predictive Insights and Resolutions

Predictive insights and resolutions optimize supply chain operations by anticipating and proactively addressing potential challenges.

Collaborative

Collaborative efforts foster innovation and efficiency, enhancing the effectiveness of supply chain operations.

3PL Control Tower

1. Service Scope: A 3PL control tower provides logistics services like transportation, warehousing, and freight management, emphasizing operational efficiency and supply chain optimization.

2. Involvement: The 3PL control tower acts as a service provider, managing specific logistics functions on behalf of the client.

3. Coordination: It coordinates and optimizes logistics activities within its area of responsibility, often focusing on specific segments of the supply chain.

4PL Control Tower

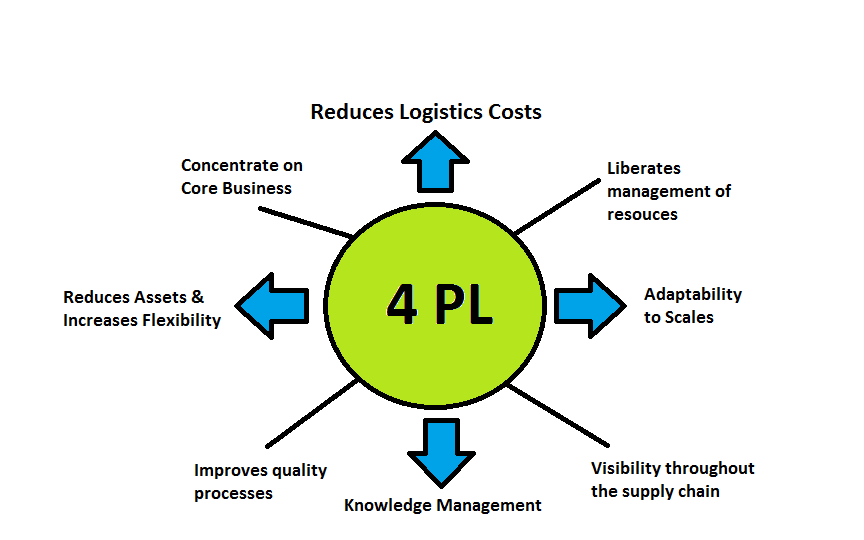

1. Service Scope: A 4PL control tower offers services beyond traditional logistics, including supply chain strategy, technology integration, and overall management.

2. Involvement: 4PL control towers act as strategic partners, overseeing supply chains and managing multiple 3PLs or service providers.

3. Coordination: It coordinates logistics providers to optimize the supply chain, emphasizing end-to-end visibility and performance.

Our Technology

Patliputra Logistics, established in 2013, has become a leader in supply chain management, first & last mile delivery, and transportation services. With a commitment to excellence, we have revolutionized the industry, providing efficient, reliable, and innovative solutions. Our dedication has earned us the trust of clients worldwide, propelling us to unparalleled success.

OMS automates order processing, inventory management, and fulfillment for efficiency.

TMS optimizes transportation, streamlining carrier selection, route planning, and payments.

WMS optimizes warehouse operations, managing inventory, orders, and logistics efficiently.

FMS optimizes freight operations, managing shipments, carriers, and logistics efficiently.